Technology

Taking a step towards better packaging

Through continuous observation and advancements, WJ improves its technology. Our pouches are designed for easy tearing and feature a flawless finish. They ensure contents remain safe and fresh.

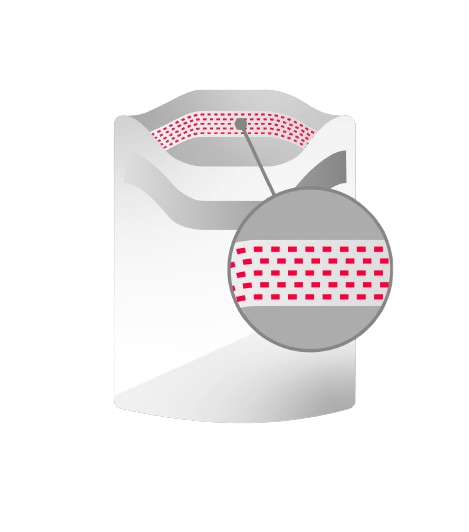

Closure

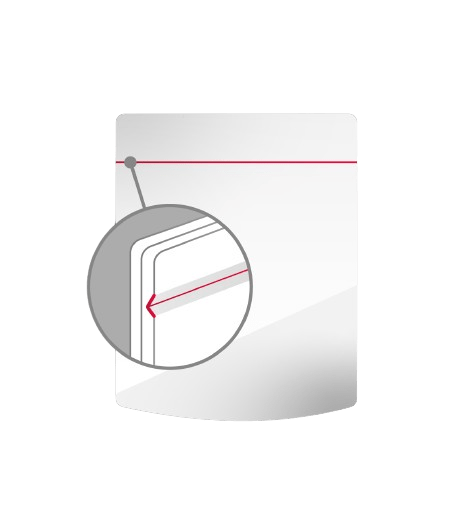

Press to close Zipper

Press to close zipper allows the consumer to resesal the packaging after opening.

Velcro/Aplix Zipper

Hook-to-Hook or Hook-and-Loop types available in many different width options.

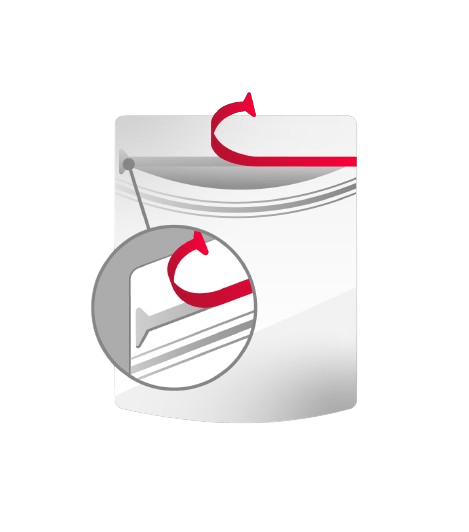

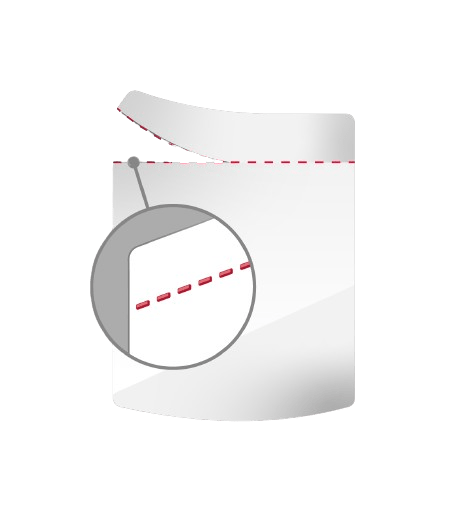

Pocket Zipper (Tear-Strip)

The packaging is easily opened using the Tear-Strip, and can be resealed with the Pocket Zipper.

Bag Finish

Matte Coating

Available in flood or partial coating, matte coating provides the premium look to the packaging.

Soft Touch Coating

Available in flood or partial coating, soft touch coating provides the premium feel to the packaging.

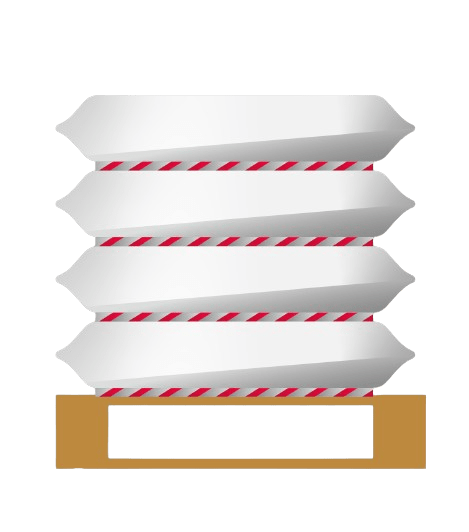

Anti-Slip Coating

Anti-slip Coating provides the grip between the bags, when they are stacked on the pallet.

Tear type

Linear Tear

Linear Tear function is added to the structure, allowing the pouch to tear open in a straight line.

Laser Score

Laser Beam is used to score a thin straight line, allowing the pouch to tear open in a straight line.

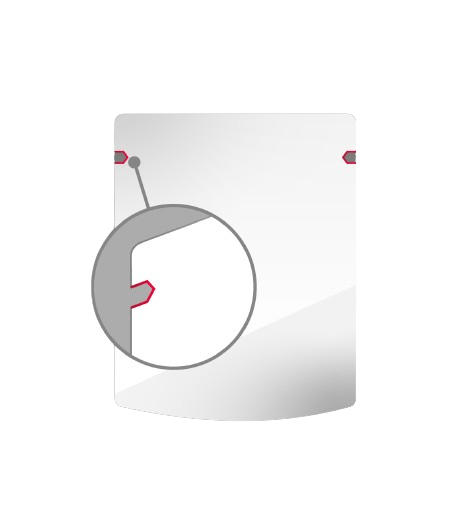

Tear Notch

Tear notch provides the starting point on the pouch, where it is meant to be torn opened.

Air Flow

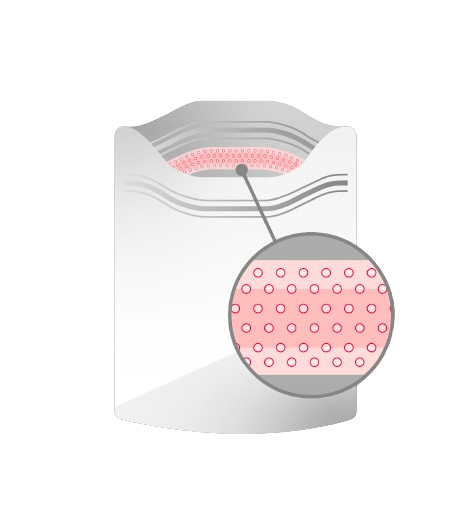

Micro Perforation

Perforation allows for ventilation in & out the pouch, and is available in different patterns.

Fiber Vent Strip

The vent strip membrane allows the bag to ventilate, while preventing any microbes from entering the bag.

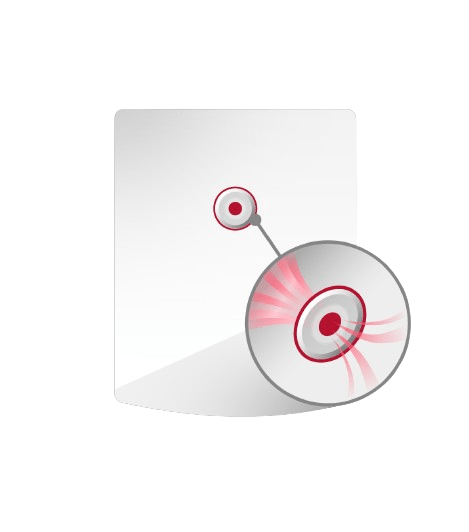

One-way Valve

Commonly used for coffee bags, these one-way valves allow the air out of the bag, while stopping air from re-entering the bag.